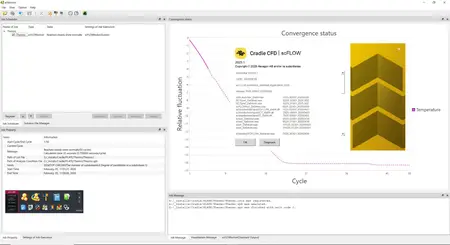

Free Download Hexagon MSC Cradle CFD 2025.1 Win x64 English | 2.6 Gb

Hexagon is proud to announce the release of MSC Cradle CFD 2025.1 as a Multiphysics Computational Fluid Dynamics solution to enhance your productivity for designing, researching, and manufacturing. The packages of scFLOW, scSTREAM, HeatDesigner, SC/Tetra, PICLS, CADthru and scPOST are all integrated into Cradle CFD.

This release features our most recent iteration in Battery safety modelling, with kinetics-driven thermal runaway added to scFLOW. Steady-state 3D-ROM files can now be visualized in scPOST and parametric studies with scFLOW have never been easier to set, submit and monitor. When using the voxel fitting mesher, facet accuracy can now be set by parts for better surface capturing. Combustion in industrial furnaces can now run very quickly by leveraging the connection between scFLOW and the LOGEacs Combustion Progress Variable (CPV) module. The simulation time when using discontinuous meshes (rotating domains) or the DEM solver is shorter, while the new AMG solver enhances robustness when dealing with coupled problems. Solid parts in porous media can now be modelled at the solver level without the need to represent complex internal geometries. Inputting large data tables in scSTREAM is now quick and easy, and blower fan components can use an outlet velocity profile. scPOST can better handle large datasets, for which waiting times and memory usage are now dramatically reduced.

Battery thermal management and safety

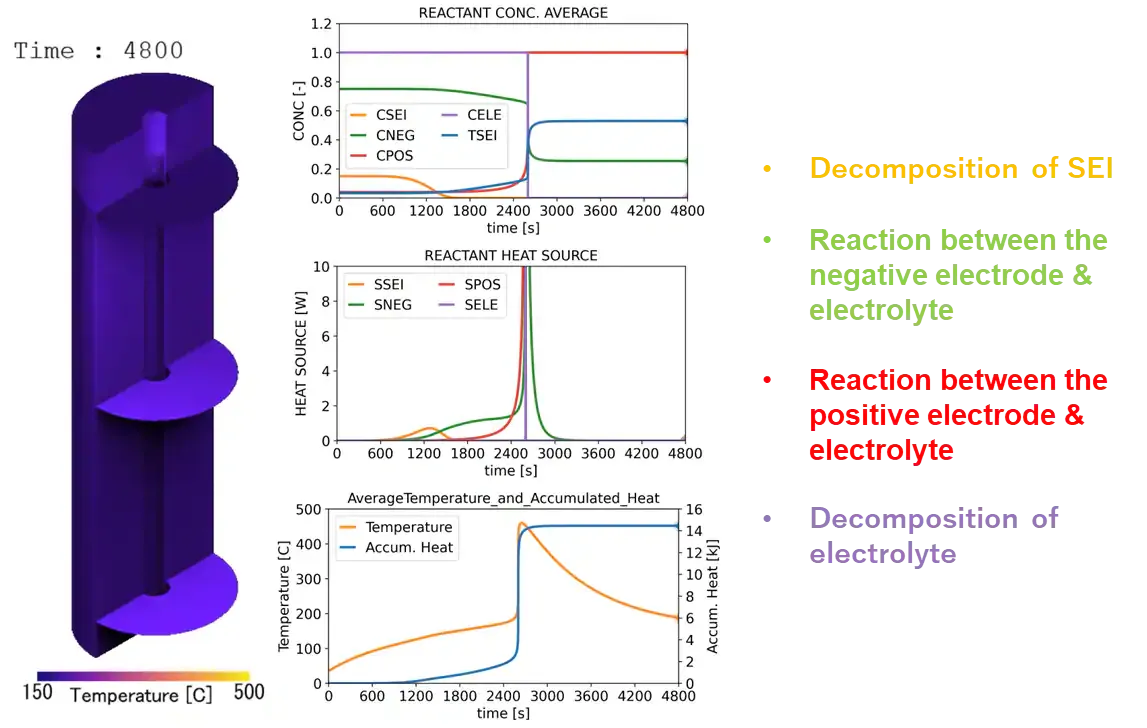

-Battery kinetics-driven thermal runaway

A new thermal model that simulates Li-ion battery thermal runaway using the Arrhenius equation has been implemented. As an alternative approach to the previously introduced semi-empirical thermal runaway model, detailed cell heat generation is now obtained without the need to feed pre-existing experimental data, but instead by directly modelling several internal phenomena like decomposition of SEI, the reaction between electrodes and electrolyte and electrolyte decomposition.

Close

-Graph display function (ARC test data pre-processing)

This feature enhances the setup process for the semi-empirical thermal runaway feature we introduced in Cradle CFD 2024.2. In the preprocessing of ARC measurement data, experimental raw data are used to extract a monotonically increasing heat generation curve and to identify the portion measured under adiabatic conditions. This data management and curve Descriptionting is now available within the GUI, making the setup process easy and less error prone. Raw data and parameters used in pre-processing can be edited and stored directly in the PPH file.

Artificial Intelligence / Machine Learning

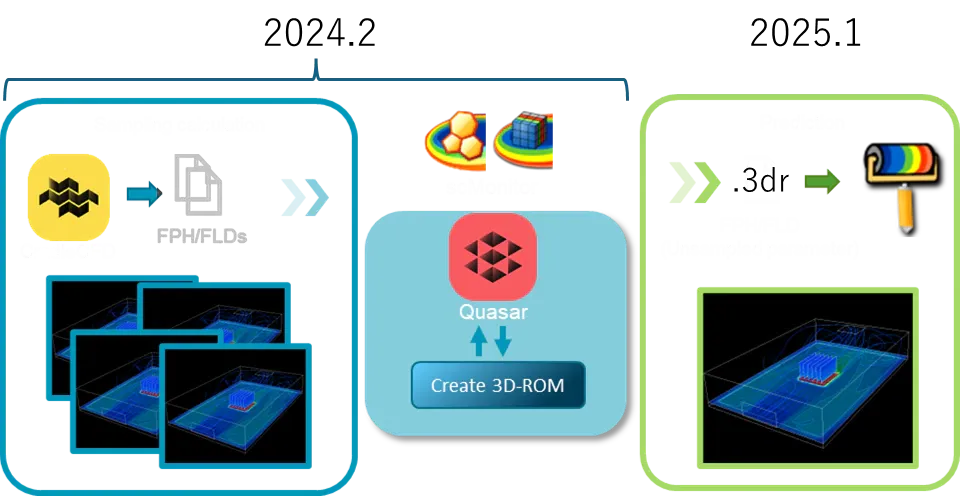

-3D-ROM via POD-ARBF (Proper Orthogonal Decomposition-Adaptive Radial Basis Function)

In the 2024.2 release, we combined the machine learning algorithms in ODYSSEE with 3D field data from scFLOW to generate reduced thermal-flow models. In this release, we added visualization of the estimated results in the Cradle post-processing environment. ROMs file (.3dr) generated by ODYSSEE can now be imported in scPOST. We currently fully support steady-state ROM and plan to add support for transient ROM visualization in one of the upcoming releases.

Close

-Enhanced control of parametric studies in scFLOW

We added parametric studies with geometry changes in Cradle CFD 2024.2 release. The "Workflow Wizard" has been enhanced with additional control when submitting and monitoring the parametric study simulations. Progress is now shown in the GUI, and the entire process can be interrupted to check on the simulation's status when an expected event occurs.

Productivity

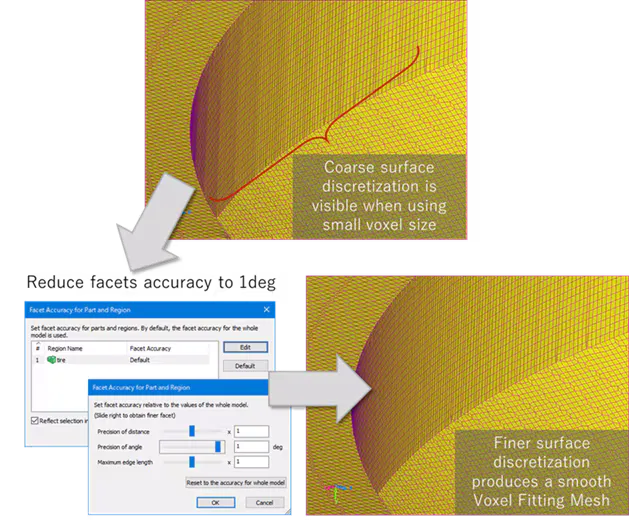

-Facets accuracy setting by parts

When using the voxel fitting mesher, users can now specify local parameters to capture with higher accuracy the CAD model shape. Previously, using a local voxel size smaller than the global facet accuracy could lead to imperfections in the meshed surfaces due to insufficient accuracy in the original CAD surface discretisation (MDL). When capturing smooth geometries is paramount, users can now specify a local facet accuracy for specific parts, which overrides global settings and guarantees a smooth final mesh.

Close

-Sweep parts enhancements

Parts that share nodes on the source face of the sweep can now be treated as sweep parts without the need to physically separate their topology, allowing multiple sweep domains to have common edges. This feature expands the usability of sweep mesh functionalities, removing a geometrical constraint that would have previously required manual fixing. Multiple sweep meshes can be more easily set to capture straight domains reducing mesh elements with a higher degree of control of element quality.

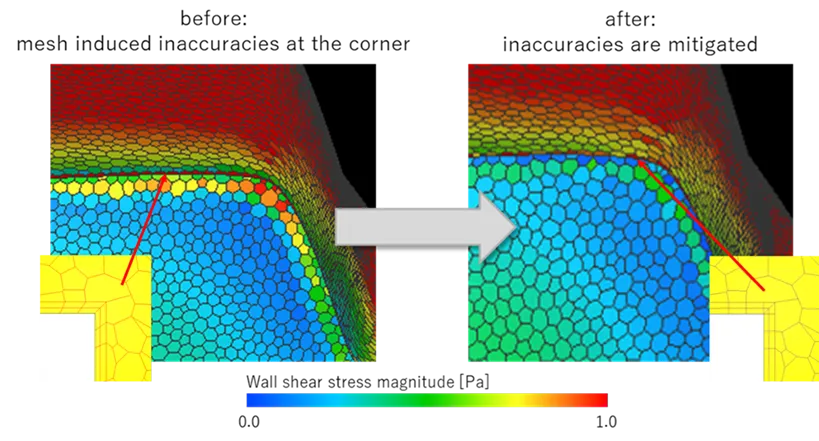

-Improved boundary layer insertion

A new algorithm for mesh prism insertion that handles better sharp edges has been introduced. Near-wall prism layers are now generated with more elements, avoiding spurious results when simulating flow around sharp edges. Results accuracy has improved, and early flow separation due to abrupt pressure changes at sharp edges is now avoided.

Close

-CGNS file import in scFLOWpre

We extended the usability of scFLOW by allowing the direct import of mesh files in CGNS format (CFD General Notation System) in scFLOWpre. Users can now import models generated by 3rd party software and use them in simulations with scFLOW. For example, meshes shared in the framework of computational workshops can now be directly used. CGNS polyhedral mesh format is also supported

scFLOW solver enhancements

-Combustion Progress Variable (CPV) approach

By leveraging the existing coupling between scFLOW and the chemical reaction solver LOGEacs, we implemented the Combustion Progress Variable (CPV) approach for combustion simulation. Based on the Well-Stirred Reactor (WSR) assumption, CPV is a fast prediction method for complex reaction mechanisms. It combines the calculation accuracy of the conventional direct chemistry approach available via LOGEacs with sensitively reduced calculation times. This model is particularly suitable to simulate industrial furnaces.

Close

Methane burner combustion simulation using LOGE CPV in scFLOW (LES)

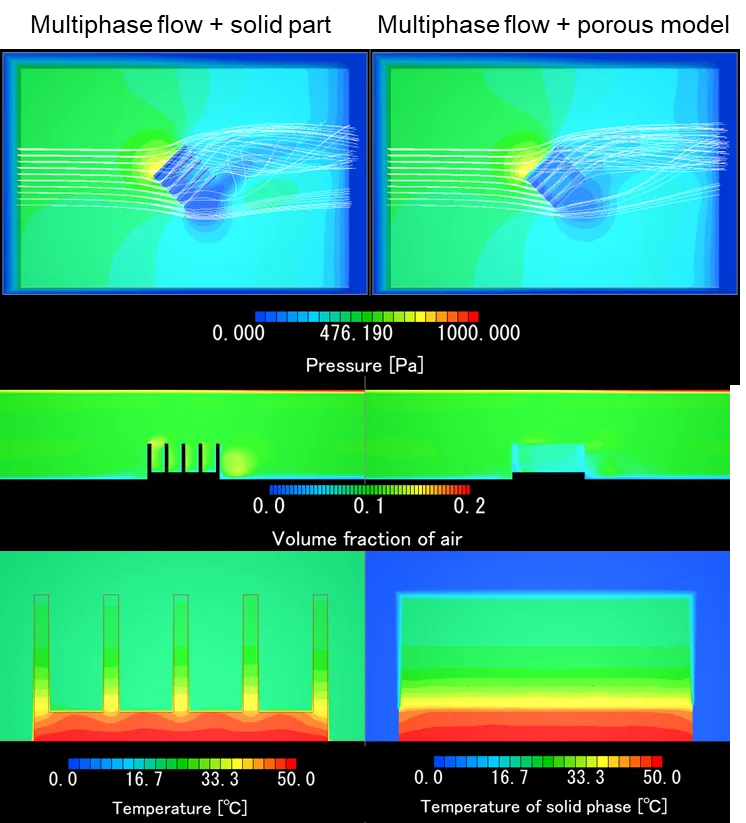

-Modelled solid phase in porous domains

In multiphase flow analysis, it is now possible to set a porous material (pressure loss body) as partially solid. With solid parts completely modelled at the solver level, direct geometrical representation is not required, reducing setup complexity and mesh size. When using this feature, both the thermal and velocity fields inside the porous media region are modified to account for the thermal inertia and porosity of the solid parts. The total thermal and momentum exchange produced by a thermal device modelled in this way is equivalent to the device modelled with solid parts.

Close

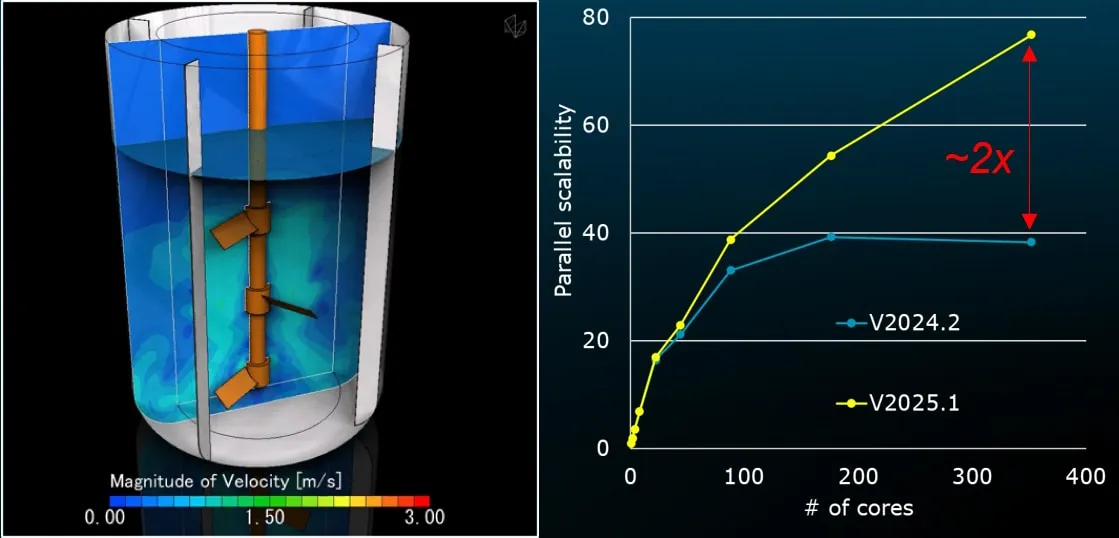

-Speed-up of analyses with discontinuous mesh

The discontinuous meshes algorithm has improved, achieving a sensitive calculation speed-up in parallel calculations. All analyses including rotating domains can expect benefits in terms of calculation times. In addition to calculation speed, scaling with increasing numbers of cores has also improved. Parallel runs using a large number of cores and multiple rotating domains are expected to see the larger benefits. Simulation speed-up has been observed in between 2x ~ 3.5x range. Actual values may vary depending on the specific model and boundary conditions.

Close

-DEM solver speed-up

Parallel computation for DEM analyses with non-uniform particle size has been improved and is now enabled by default. An efficient contact detection algorithm (Bounding Volume Hierarchy, BVH) is available as an option for both uniform/non-uniform particle sizes. When comparing with Cradle CFD 2024.2 results, a 30% reduced calculation time has been observed when using the default contact detection algorithm. This reduction reaches 45% by using the BVH contact detection algorithm. Actual simulation time reduction may vary depending on the number of particles and the specific simulation setup used.

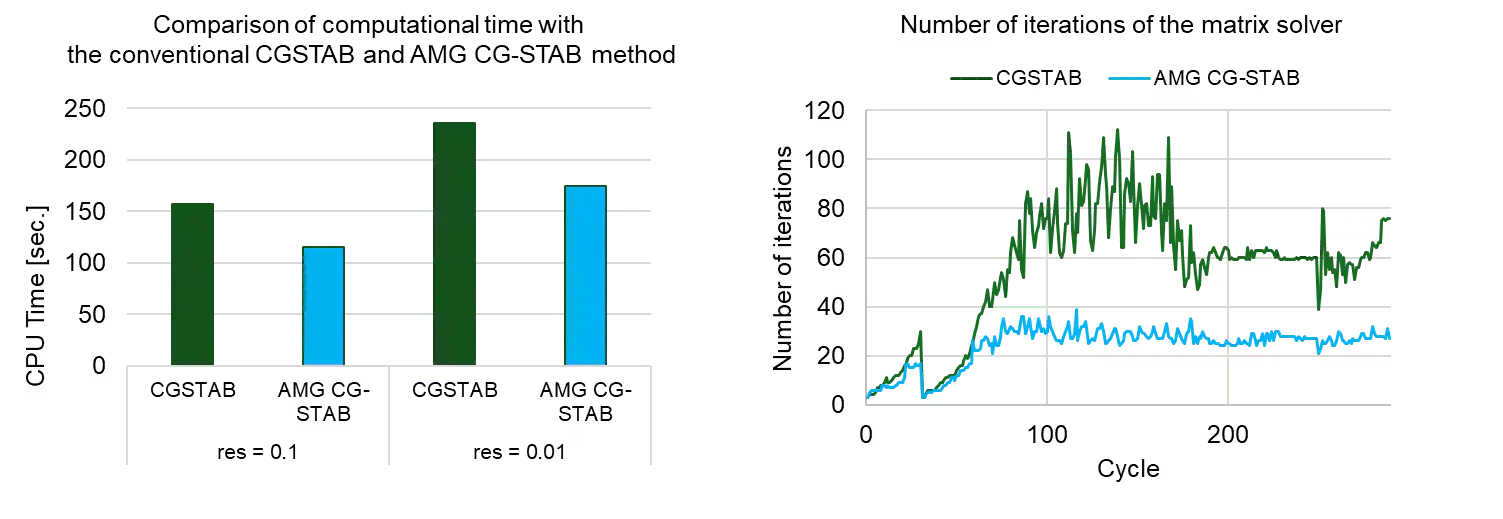

-Implementation of Algebraic Multi Grid (AMG)

The Algebraic Multi Grid (AMG) CG-STAB (Stabilized Conjugate Gradient) solver, which employs the algebraic multigrid method (AMG) as a preconditioner, can now be used to solve also coupled systems (previously available only for the segregated pressure-based solver). AMG CG-STAB method can solve a matrix with fewer iterations than the conventional CG-STAB method. When using this solver, a reduction in the number of iterations per cycle needed for convergence can be seen, which in general leads to a reduction in computational time. This new step forward in our solver capabilities is the foundation for further improvements targeting large, coupled equations systems.

Close

scSTREAM solver enhancements

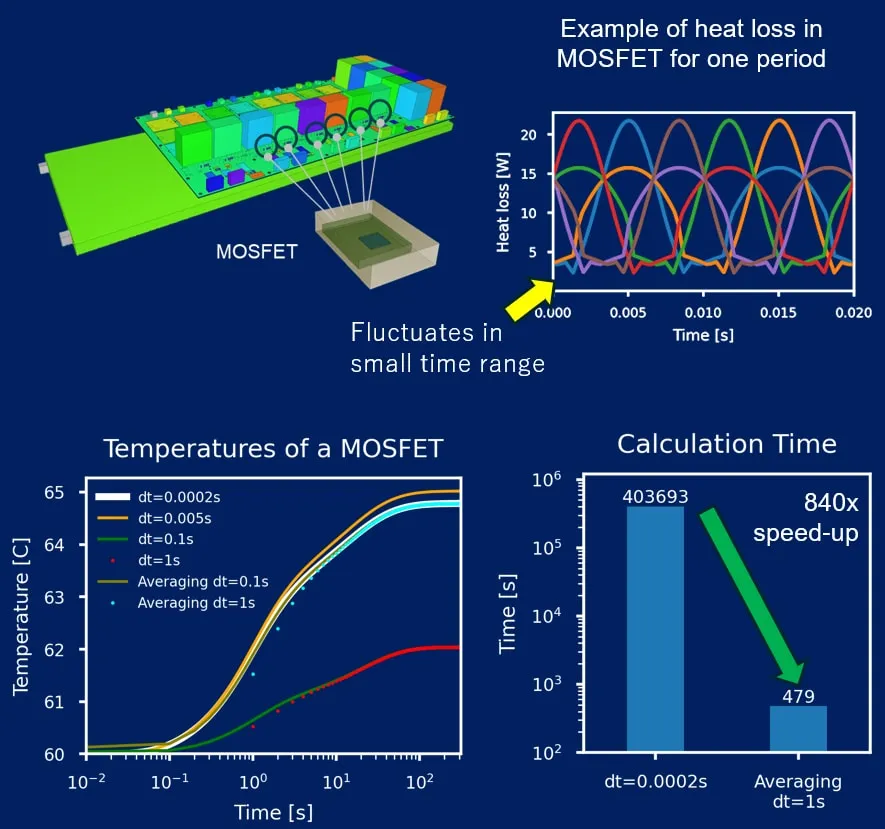

-Data table handling

Various new options are now available when using time-dependent data tables, such as different interpolation methods, out-of-table behaviour, periodic data simplified input and an option to enable time averaging. Setup of a periodic table for example can now be performed quickly by including only the portion of data relative to one period and enabling periodicity. Time-averaging is useful when dealing with data sampled at very high frequencies. In this situation, which can be the case of the heat generated by an electronic device working at high frequency, the tabled data timestep can be smaller than the one used in the simulation. Time-averaging of tabled data ensures that the correct total power enters the domain, without limiting the simulation timestep, potentially reducing computational time for long transient analyses.

Close

-Velocity profiles in a blower fan model

In blower fans, flow circulation inside the volute causes the exit flow velocity to be unevenly distributed. When using the blower fan component, it is now possible to assign, in addition to the P-Q characteristics, a non-uniform velocity profile to mimic the actual device exit flow. This feature produces more accurate flow distributions in thermal devices using blower fans and more correct flow interactions with downstream components.

Close

-Automatic pressure fix for isolated cut-cell volumes

When using cutcell, many small, isolated volumes can be generated when very complex devices are simulated. This is not a modelling error but derives from the fluid volume extraction operation. In isolated fluid volumes, pressure can assume arbitrary values and lead to calculation divergence. A default pressure value can be now fixed for such isolated volumes, avoiding convergence issues without direct user intervention. Generally, simulations using the cutcell approach are now more robust.

Post-processing

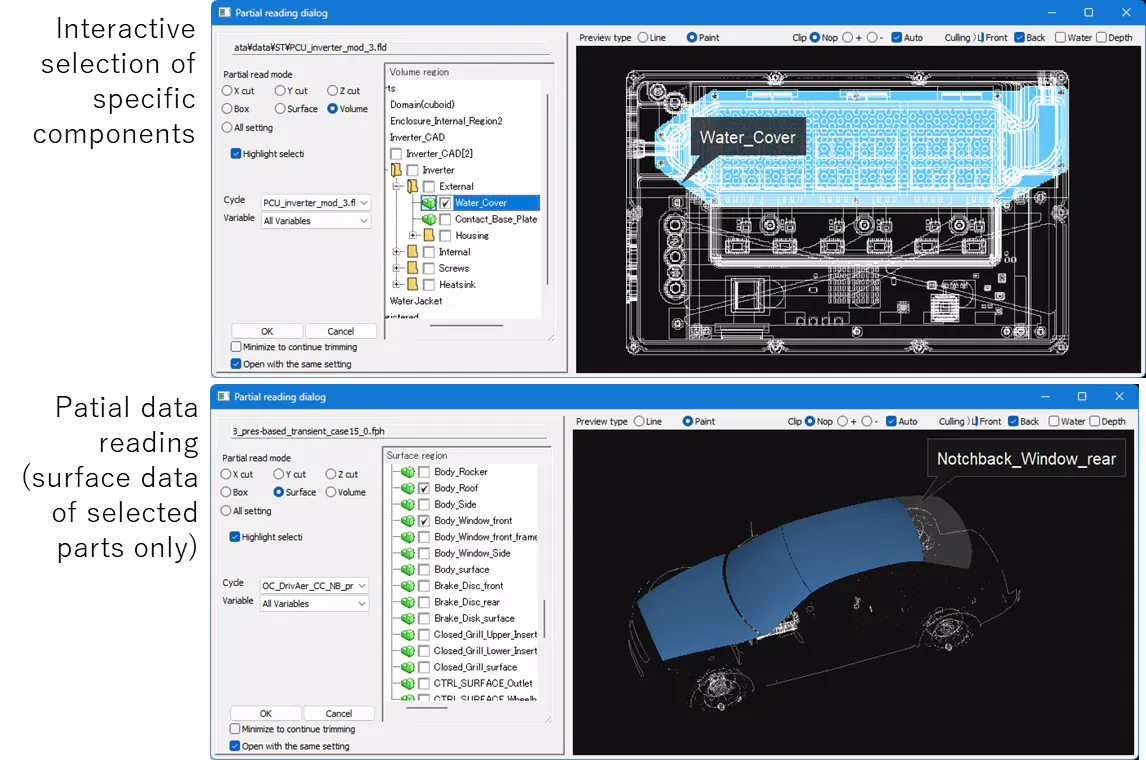

-Enhanced preview for large-scale datasets

In Cradle CFD 2024.2 release, we introduced the preview functionality for large-scale results files. In 2025.1 we introduced a new enhancement with the option to select components to display by name or via mouse click in the preview window. This offers an easy and intuitive way to isolate only the components of interest, loading only these into scPOST. Reducing the data import to only selected components reduces dramatically data reading time and memory usage, making it possible to process large model results on machines with limited resources.

Close

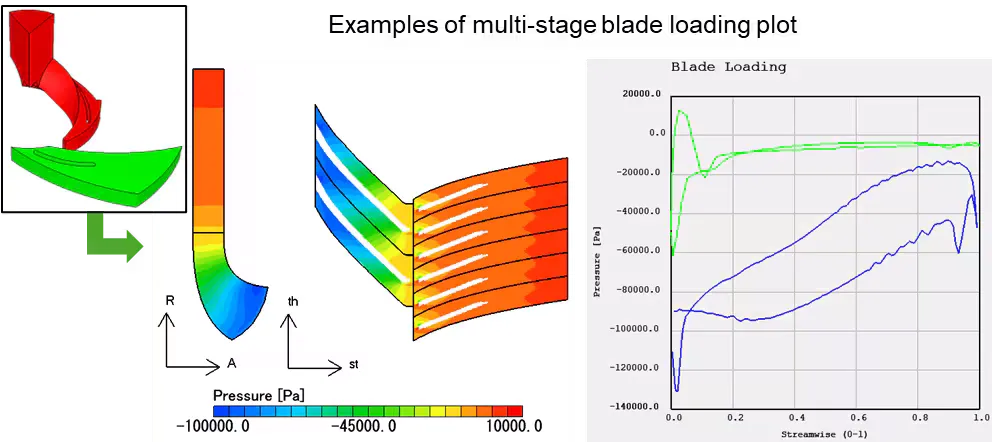

-Visualization for turbomachinery

We improved the setup of multiple stages and the calculation of velocity components, which are now supported in a specialized tab. Automatic region name settings can be specified, and options for additional Descriptions are now available.

Close

-Real particle size in CradleViewer

For particle simulation using different particle sizes, scPOST can now export particle size information to CradleViewer which can visualize the actual size of each particle. Visualizations in CradleViewer offer now similar visuals for the same dataset opened in scPOST.

Other enhancements

Productivity:

- Model Wizard: automatic detection and imprinting of imprint-failed edges.

- Voxel Fitting Mesher: post-processing options for shape reproducibility.

scFLOW:

- scFLOW2Actran: wall acoustics absorption condition has been added.

scSTREAM:

- The JOS-3 human model is now available with full GUI support.

- Heat source as volumetric heat generation and Joule heat can be output in flow field results.

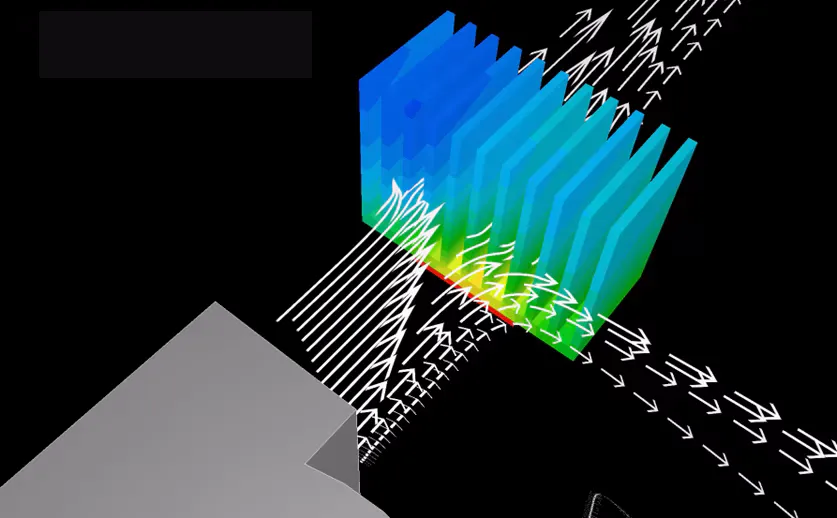

Cradle CFDis a series of practical, state-of-the-art CFD simulation and visualization software. Embracing remarkable processing speed, refined technology, and proven practicality verified by high user satisfaction, it has been in use for diverse applications, such as Automotive, Aerospace, Electronics, Building and Architecture, Civil Engineering, Fans, Machinery, and Marine developments, to solve thermal and fluid problems. Incorporating the reinforced Multiphysics co-simulation and chained simulation capability to achieve couplings with Structural, Acoustic, Electromagnetic, Mechanical, One-Dimensional, Optimization, Thermal Environment, 3D CAD and other relative analysis tools, as well as award-winning postprocessing feature to generate visually powerful simulation graphics, Cradle CFD enables any level users to process advanced simulations.

Cradle CFD Orthogonal Mesh Technology - Meshing Complex Electronics Models Quickly

Hexagonis a global leader in sensor, software and autonomous solutions. We are putting data to work to boost efficiency, productivity, and quality across industrial, manufacturing, infrastructure, safety, and mobility applications. Our technologies are shaping urban and production ecosystems to become increasingly connected and autonomous - ensuring a scalable, sustainable future.MSC Software, part of Hexagon's Manufacturing Intelligence division, is one of the ten original software companies and a global leader in helping product manufacturers to advance their engineering methods with simulation software and services.

Software Cradle is a Japanese firm highly valued as an innovative computational fluid dynamics (CFD) software vendor in the automotive, turbomachinery, electronic, building and civil engineering sectors. MSC Software Corporation acquired all of the shares of Software Cradle and Software Cradle has become an MSC Software company.

Owner:Hexagon AB

Product Name:MSC Cradle CFD

Version:2025.1

Supported Architectures:x64

Website Home Page :

Code:

https://hexagon.com/System Requirements:Windows *

Size:2.6 Gb

Recommend Download Link Hight Speed | Please Say Thanks Keep Topic Live

Rapidgator-->Click Link PeepLink Below Here Contains Rapidgator

http://peeplink.in/77e160f4aa12

Password: 123

DDownload

a7icm.Hexagon-MSC-Cradle-CFD-2025-1.rar

FreeDL

a7icm.Hexagon-MSC-Cradle-CFD-2025-1.rar.html

Links are Interchangeable - No Password - Single Extraction